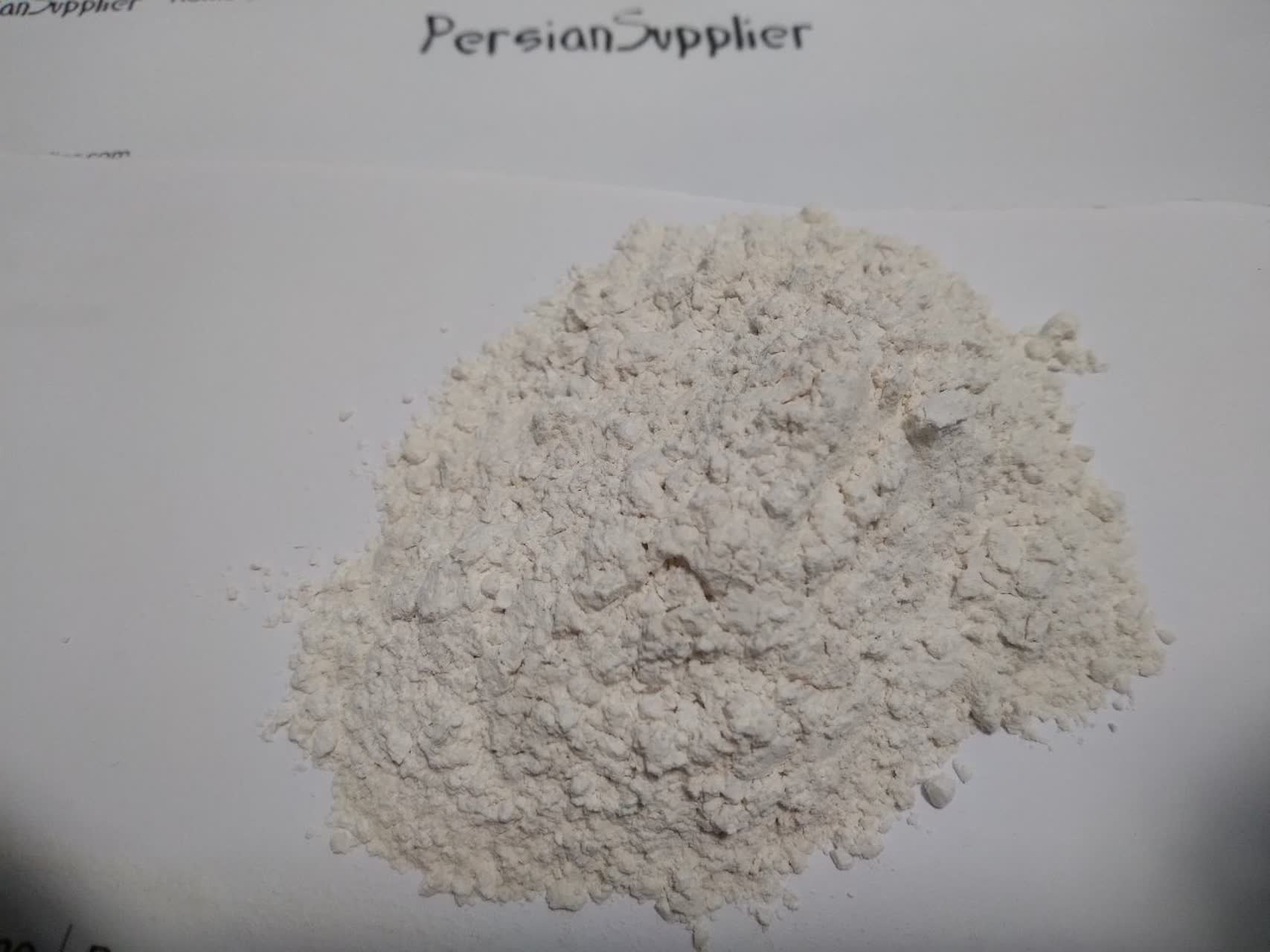

Silica Powder: Essential for Durability and Innovation in Manufacturing

Silica Powder is a versatile mineral driving efficiency in construction and beyond. At Mineral Supply Hub PersianSupplier, we export high-purity Silica Powder to the Persian Gulf, serving industries in Bahrain, UAE, and Saudi Arabia. Discover how this powder elevates your products.

Contact us today for a technical datasheet, sample, or custom quote:

- 🌐 www.persiansupplier.com

- 📧 info@persiansupplier.com

- 📱 +98 912 280 5524 (WhatsApp/Telegram available)

What is Silica Powder? Silica Powder: Essential for Durability

Silica Powder is finely milled silicon dioxide, known for its hardness and stability. It’s available in various grades for industrial and agricultural use.

Key Applications of Silica Powder

Versatile in:

- Construction: Strengthens concrete, mortar, and asphalt for roads and buildings in the Gulf.

- Glass and Ceramics: Key ingredient for durable glass in architectural projects.

- Agriculture: Enhances soil health and crop resistance in arid farming regions like Qatar.

- Cosmetics and Paints: Absorbs oils for matte finishes in beauty products and coatings.

- Rubber and Plastics: Improves elasticity and wear resistance.

It supports the region’s infrastructure and export sectors.

Benefits of Using Silica Powder

Offers: Silica Powder: Essential for Durability

- Enhanced Strength: Boosts mechanical properties and sulfate resistance in concrete.

- Chemical Stability: Resists harsh environments, ideal for Gulf oil and gas industries.

- Agricultural Gains: Improves yield, disease resistance, and water efficiency.

- Cost-Effective: Reduces stress and enhances product longevity.

It can minimize water loss in plants, vital for desert agriculture.

Why Choose Mineral Supply Hub PersianSupplier for Silica Powder?

Our Silica Powder is pure and customizable, with fast shipping to Gulf ports. Trust our expertise for reliable supply.

Contact us today for a technical datasheet, sample, or custom quote:

- 🌐 www.persiansupplier.com

- 📧 info@persiansupplier.com

- 📱 +98 912 280 5524 (WhatsApp/Telegram available)

10 Frequently Asked Questions (FAQs) About Silica Powder: Essential for Durability and Innovation in Manufacturing

Below are 10 detailed FAQs about silica powder, its properties, applications, and safety considerations, tailored for manufacturers, engineers, or users. These are based on common industry queries and reliable sources like OSHA, Wikipedia, and specialized chemical material websites. Each answer provides in-depth explanations, examples, and practical insights.

1. What is silica powder, and what is it made of?

Silica powder, or silicon dioxide (SiO₂), is a naturally occurring mineral derived from the Earth’s crust and processed into a fine powder. It exists in crystalline forms (e.g., quartz, sand) or amorphous forms (e.g., fumed silica). Industrial silica powder is often high-purity (99%+), produced through processes like crushing silica-rich rocks or chemical synthesis. Its key properties include high hardness (7 on the Mohs scale), thermal stability (up to 1600°C without decomposition), and excellent chemical resistance. In manufacturing, it serves as a filler, reinforcer, or base material, enhancing durability in products like cement, glass, or electronics.

2. What are the main industrial applications of silica powder?

Silica powder is critical across industries for durability and innovation. In glass and ceramics, it’s a primary component (up to 70% of the mix) for heat-resistant borosilicate glass, like labware. In concrete and cement, adding 5-15% silica increases compressive strength by up to 30% and reduces water permeability. In plastics and rubber, it enhances abrasion and tear resistance, as seen in car tires. In electronics, high-purity silica is used for insulating semiconductor chips and optical fibers. It’s also used in coatings for UV-resistant, matte finishes, in metallurgy for lightweight alloys (e.g., aluminum-silicon), and in composites for aerospace, enabling innovations like lightweight, high-strength materials.

3. How does silica powder improve the durability of manufactured products?

Silica powder enhances durability through its unique physical and chemical properties. Its high hardness, due to strong covalent bonds, makes materials more resistant to wear and impact; for example, adding 20-30% silica to rubber extends tire life by up to 20%. Its thermal stability ensures materials withstand high temperatures (e.g., in industrial furnaces) without deforming, critical for jet engine ceramics. Chemically, silica resists corrosion from acids and moisture, making it ideal for coatings and sealants. In concrete, microsilica fills microscopic voids, reducing cracks and increasing lifespan by 15-20 years in structures like bridges.

4. What types of silica powder are available for industrial use?

Silica powder comes in several forms, each suited for specific applications:

- Crystalline Silica: Includes quartz or sand, used in construction (e.g., concrete) and glassmaking due to its abundance and low cost.

- Fumed Silica (Amorphous): A fine, lightweight powder used in paints, adhesives, and rubber for its high surface area (up to 400 m²/g).

- Precipitated Silica: Chemically synthesized for precise particle sizes, ideal for tires and plastics.

- Colloidal Silica: A liquid suspension used in polishing semiconductors or as a binder in ceramics. Each type is selected based on particle size, purity, and application needs, with amorphous forms being safer due to lower health risks compared to crystalline silica.

5. Is working with silica powder safe, and what precautions are needed?

Silica powder, particularly crystalline silica, poses health risks if inhaled as dust, potentially causing silicosis, a lung disease, or increasing lung cancer risk (per OSHA guidelines). Amorphous silica is generally safer but still requires caution. Precautions include:

- Ventilation: Use dust extraction systems in workplaces.

- Personal Protective Equipment (PPE): Wear N95 respirators or higher and protective goggles.

- Wet Processing: Dampen silica to reduce airborne dust during handling.

- Regulations: Follow OSHA’s silica standard (e.g., permissible exposure limit of 50 µg/m³). Manufacturers should train workers, monitor air quality, and use enclosed systems for high-dust processes like grinding or mixing.

6. How does silica powder contribute to innovation in manufacturing?

Silica powder drives innovation by enabling advanced materials and processes. In electronics, ultra-pure silica is critical for producing silicon wafers, enabling smaller, faster microchips (e.g., 5nm chips in modern smartphones). In composites, silica nanoparticles enhance strength-to-weight ratios, used in aerospace for fuel-efficient aircraft parts (e.g., Boeing 787 components). In renewable energy, silica-based aerogels provide superior insulation for solar panels. Its versatility allows manufacturers to develop sustainable products, like low-rolling-resistance tires that reduce fuel consumption by 5-7%, aligning with green manufacturing trends.

7. What are the benefits of using silica powder in coatings and paints?

In coatings and paints, silica powder improves durability and performance. It acts as a matting agent, creating smooth, non-reflective surfaces (e.g., in automotive paints). Its UV resistance prevents fading, extending coating lifespan by 5-10 years. Silica also enhances scratch resistance and adhesion, critical for industrial coatings on machinery. For example, adding 2-5% fumed silica to epoxy coatings increases abrasion resistance by 30%. Additionally, silica improves flow control, ensuring even application, and is cost-effective, reducing reliance on expensive additives.

8. How does silica powder affect the cost of manufacturing?

Silica powder is generally cost-effective due to its abundance (sand is a primary source) and versatility. Bulk crystalline silica costs $50-150 per ton, while high-purity fumed or precipitated silica ranges from $1,000-5,000 per ton, depending on particle size and processing. In manufacturing, silica reduces costs by replacing pricier additives (e.g., in rubber or plastics) while improving product lifespan, cutting maintenance expenses. For instance, adding silica to concrete reduces long-term repair costs by 20-30%. However, safety compliance (e.g., dust control systems) may add 5-10% to operational costs.

9. Can silica powder be used in sustainable manufacturing?

Yes, silica powder supports sustainable manufacturing. Its natural abundance reduces reliance on synthetic materials, lowering environmental impact. In green construction, microsilica in concrete reduces cement use (a high-CO₂ material) by 10-15%, cutting emissions. In tires, precipitated silica lowers rolling resistance, improving vehicle fuel efficiency by up to 7%. Silica-based aerogels in insulation reduce energy loss in buildings by 30-50%. Recycling silica from industrial byproducts (e.g., fly ash) further enhances sustainability, aligning with circular economy goals.

10. How should manufacturers choose the right silica powder for their needs?

Choosing the right silica powder depends on application, budget, and performance requirements:

- Particle Size: Finer powders (e.g., fumed silica, 5-50 nm) suit high-tech applications like electronics; coarser powders (e.g., quartz, 10-100 µm) are better for construction.

- Purity: High-purity silica (>99.9%) is essential for semiconductors; lower purity suffices for cement.

- Form: Amorphous silica for paints or rubber; crystalline for glass or concrete.

- Cost vs. Performance: Balance cost (e.g., $100/ton for sand vs. $2,000/ton for fumed silica) with desired outcomes (e.g., strength or aesthetics). Manufacturers should consult suppliers, test samples, and consider regulatory compliance (e.g., REACH or OSHA) to ensure optimal selection.

title content

Toggle